- How2Recycle® Prequalification for Store Drop-Off Labeling

- APR Critical Guidance Recognition for EVOH, PA6 and now PA6,66

- Excellent results from independent testing at PFE

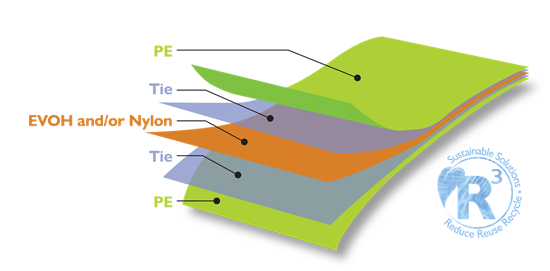

Now you don’t have to compromise when your products need the protection of multilayer barrier film and the recyclability of mono-material PE films. ReVive™ 311A Compatibilizer allows you to do both.

ReVive 311A Compatibilizer has attained How2Recycle® Prequalification for Store Drop-off labeling from the Sustainable Packaging Coalition (SPC) for multilayer packaging containing EVOH and PA6. Recently, ReVive has also received Critical Guidance Recognition for PA6,66.

ReVive 311A, when added to multilayer barrier films made with EVOH, PA6, PA6,66 or a combination of these materials, has been recognized by the Association of Plastics Recyclers (APR) as meeting or exceeding the strictest requirements for Critical Guidance Protocol for PE Film and Flexible Packaging.

ReVive 311A maintains excellent flow properties at low letdown ratios, as validated by Plastics Forming Enterprises (PFE) and leading industry partners.

Post-industrial and post-consumer barrier films made with ReVive 311A can be reprocessed back into the polyolefin recycling stream and used again for film production or other downstream plastics processing. Even if PIR/PCR films were not made with ReVive 311A, they can be reprocessed into PE films by adding ReVive 311A during the recycling process.

For more information about ReVive 311A™ Compatibilizer and other R3 Sustainable Solutions, their applications and complete regulatory status, please complete the product inquiry form.

For more information aboutHow2Recycle contact how2recycle@greenblue.org