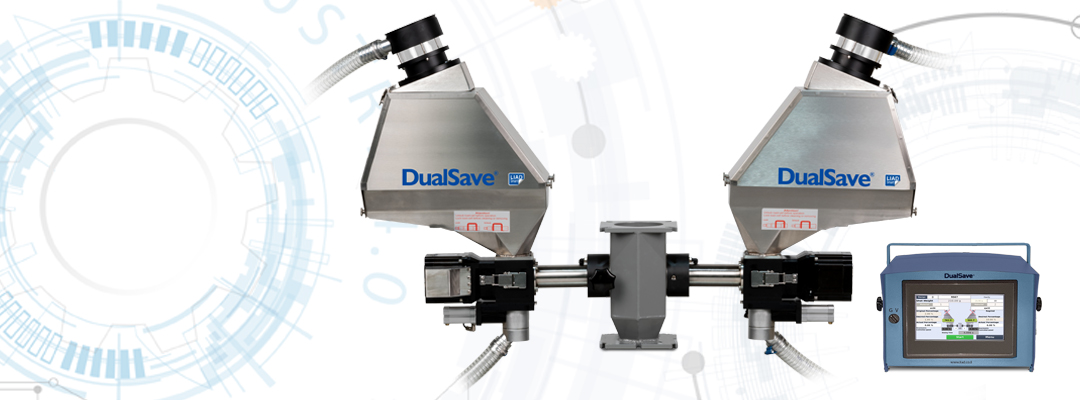

Ultra-precise dosing for two ingredients

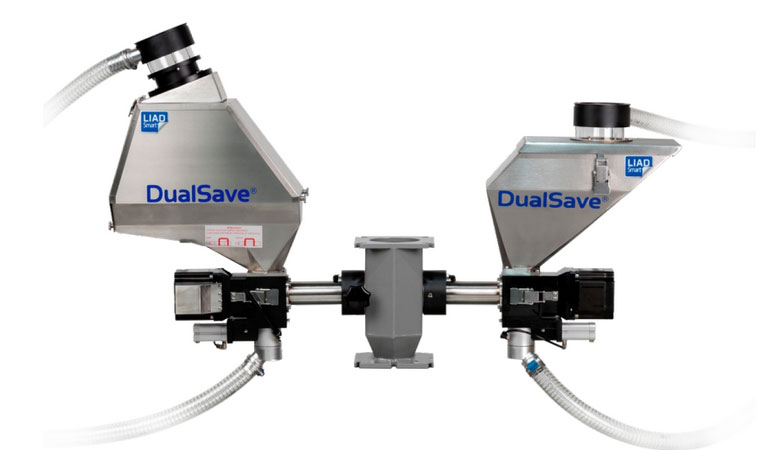

DualSave precision double dosing system uses a single control to regulate two feeders connected to a single neckpiece. DualSave assures consistent and precise operation for either gravimetric or volumetric feeding to significantly reduce rejects and improve quality of the final product and save money.

DualSave advantages

- Unparalleled accuracy and precision

- Easy to use intuitive control unit

- Improved quality of final product, fewer rejects

- Stores up to 500 recipes, saves set up time

- Compensates MB amount when using regrind

- Economical alternative to batch blenders

Multiple processes

- Injection molding

- Extrusion

- Extrusion blow molding

DualSave exclusive Automatic Compensation feature

The DualSave controller contains a built-in compensation feature that can be used when one of the hoppers is volumetric and feeding regrind and the other hopper is feeding masterbatch either gravimetrically or volumetrically. Since the regrind already contains color or additives, you can reduce the amount of colorant or additive fed from the other hopper. This exclusive DualSave feature reduces human error to enhance quality and provide substantial production cost savings.

For example, if a recipe calls for 5% masterbatch in one hopper and 20% regrind in the other hopper, DualSave automatically reduces the masterbatch percentage to 4%. Increasing the regrind to 40% reduces the masterbatch to 3%. A sensor in the regrind hopper returns the setting to its original percentage when there is no more regrind.

Available with volumetric or gravimetric hoppers

Volumetric hoppers-6, 12, 20 L capacities

Gravimetric hoppers-3, 5, IO L capacities

DualSave with 3L gravimetric hoppers with optional Venturi loaders

DualSave with 6L volumetric hopper and 3L gravimetric hopper with optional Venturi loaders

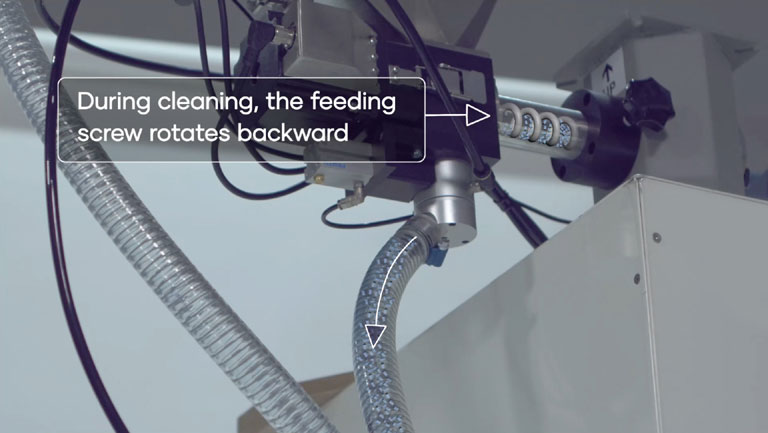

Smart Clean Feature

The SmartClean option automates the cleaning process when changing materials. With a simple push of a button, this feature uses compressed air to evacuate the material from inside the hopper and feed screw automatically, ensuring operator safety and minimizing downtime. With DualSave’s self-cleaning SmartClean option, manufacturers can achieve higher productivity, reduce manual cleaning efforts, improve operator safety, and maintain the highest production standards.

For a more detailed discussion about DualSave download product literature, call Doug Brownfield at 914-320-1521 or contact Ampacet.