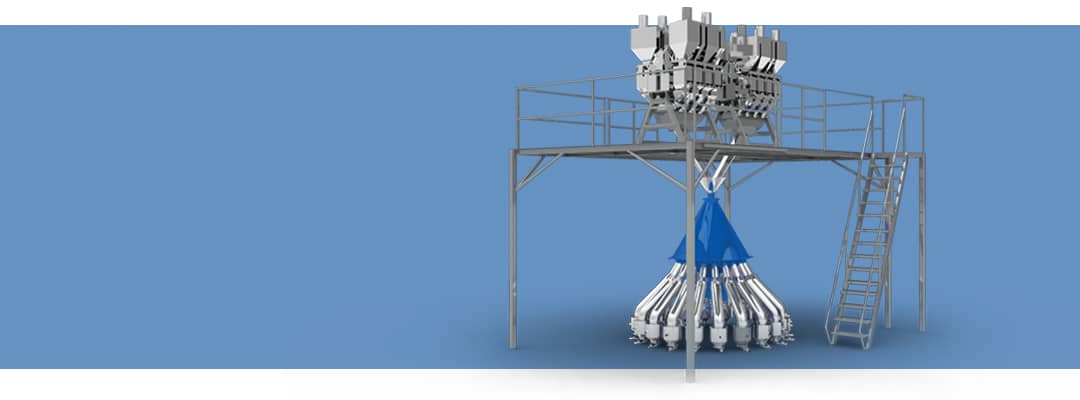

Automated Resin Blending and Management System

Simplify and streamline workflow processes while facilitating “lights out” operations

No other blending process creates customized recipes and automatically distributes them with no operator interface and zero cross-contamination.

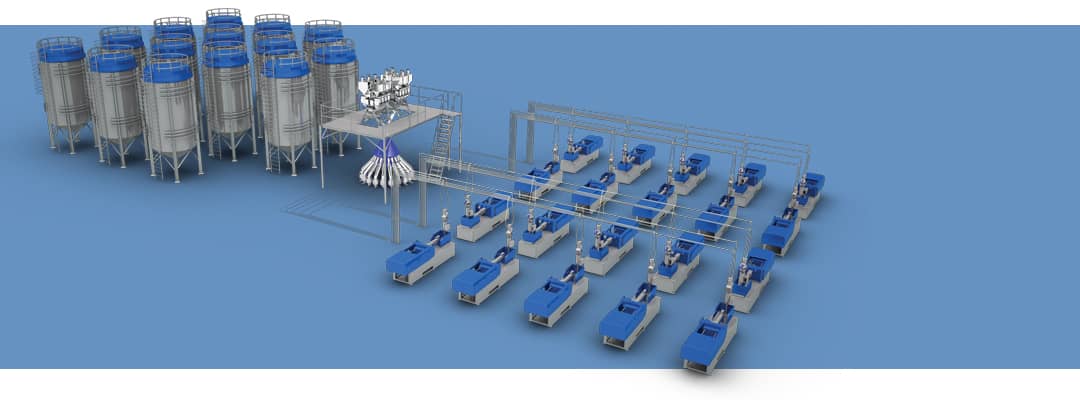

Whether you have 8 or 40 ingredients, 5 or 50 machines, BlendSave delivers the blending flexibility you need for today’s operations.

BlendSave’s modular design manages throughput from1,500 lbs./hr. to over 8,000 lbs./hr., in a footprint as small as 120 sq. ft.

Flexibility: Delivers any recipe to any machine at any time.

Precision: Each ingredient is weighted separately for a precise batch.

Cost savings: No equipment clean-outs, no hoses to switch, no mistakes.

BlendSave’s unique, dedicated recipe transfer design (OctoBatch™) eliminates sending the wrong recipe to the wrong machine.

No more complex hose configurations; no operator error.

For a more detailed discussion about how BlendSave reinvents plastic resin blending, view the white paper, watch the video, download product literature, call Doug Brownfield at 914-320-1521 or contact Ampacet.