To download PDF version click here

Introduction

Plastic manufacturers today are focused on Industry 4.0 compliance as it becomes a universal standard so they are able to quickly react to industry changes in the current fast-paced competitive environment. This fourth industrial revolution enhances computers and automation with smart and autonomous systems.

Plastic manufacturers today are focused on Industry 4.0 compliance as it becomes a universal standard so they are able to quickly react to industry changes in the current fast-paced competitive environment. This fourth industrial revolution enhances computers and automation with smart and autonomous systems.

In the highly competitive plastics industry, capital expenditure considerations are crucial to the bottom line. The high costs associated with expensive auxiliary machinery coupled with factory space, manpower and long-term maintenance demand that manufacturers reconsider how they manage, convey, weigh, blend and feed all the raw materials that go into individual formulations while ensuring uptime and quality.

Challenges to Plastic Resin Blending

The current methodology of resin blending, central blending and blending next to or on-top of the processing machine poses significant challenges such as:

- Material segregation during conveying

- Homogenizing multiple batches to ensure accuracy of the blend

- Labor and clean down time of each batch blender

- Lost uptime for product changes

- Capital cost of having a batch blender for every line

- Centralized control of all individual batch blenders

- Complicated vacuum systems

- Mezzanines for each batch blender

BlendSave® – Resin Blending Re-invented

Ampacet’s LIAD Smart Technology brings a revolutionary Industry 4.0 innovation to the plastic processing industry addressing the challenges of raw material automation in weighing, conveying and blending. LIAD Smart addresses the wasteful, inefficient and overly complex manner of weighing, blending and conveying raw plastic material. Standard gravimetric batch blenders weigh batch components in serial order, while homogenizing 3 batches to ensure accurate weighing.

Ampacet’s LIAD Smart Technology brings a revolutionary Industry 4.0 innovation to the plastic processing industry addressing the challenges of raw material automation in weighing, conveying and blending. LIAD Smart addresses the wasteful, inefficient and overly complex manner of weighing, blending and conveying raw plastic material. Standard gravimetric batch blenders weigh batch components in serial order, while homogenizing 3 batches to ensure accurate weighing.

To meet this challenge, LIAD developed BlendSave, a patented centralized multi-ingredient gravimetric batch blending automation system able to provide optimal management of multi ingredients and multi-processing machine combinations for plastics plants. Featuring precision weighing of each ingredient and segregation free blending in-line.

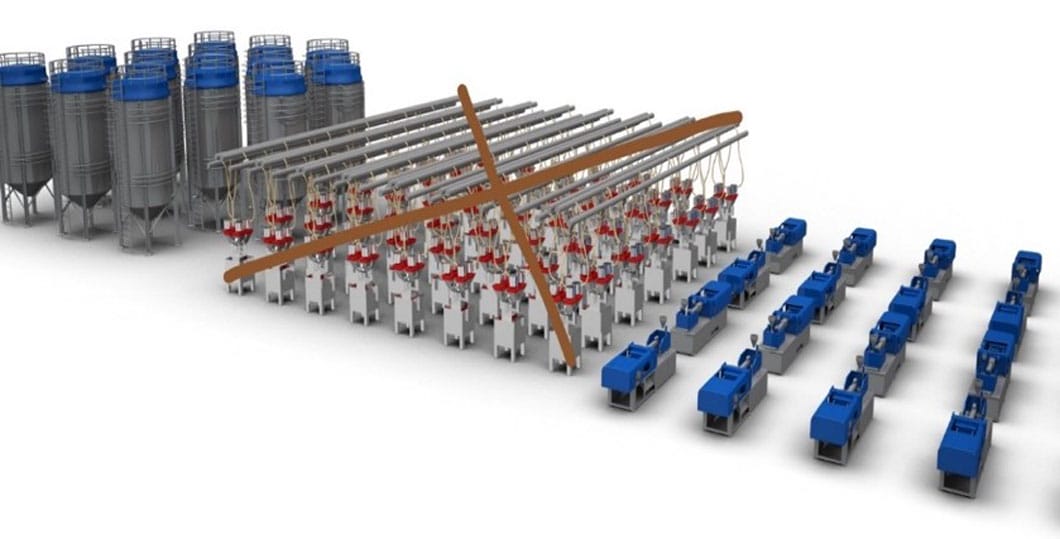

BlendSave can optimally manage combinations of ingredients across multiple processing machines in plastics plants, offering unparalleled consistency and high throughput. According to factory specifications, multiple BlendSave systems can communicate with each other, creating a platform that is virtually unlimited in the amount of raw materials and recipes that can be processed, as well as how many processing machines can be serviced.

BlendSave Capabilities

BlendSave’s centralized resin blending system accommodates up to 40 individual weighing chambers, fed directly from silos or containers, and can serve up to 50 processing machines with a potential throughput of up to six tons per hour.

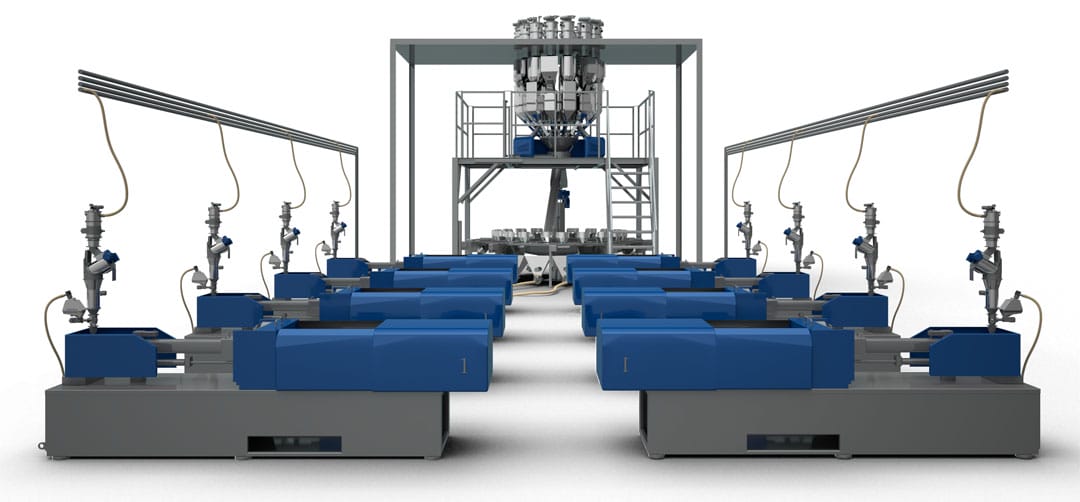

BlendSave is configured to simultaneously and accurately weigh raw materials, combining them as a batch according to a predetermined recipe destined for predetermined processing machines. Each batch is then distributed via a rotating-arm-dispenser to its own buffer comprised of up to 50 batch buffer bins, with each buffer linked to one, dedicated processing machine. Once a signal is received from a vacuum receiver mixer/blender located at the inlet of the processing machine, material from the linked buffer is transferred via a delivery pipe to the mixer. The volume within a buffer bin and that of the linked mixer is adjusted so that the second can accommodate the first, producing exceptional batch uniformity. Blending in-line prevents the risk of material segregation during conveying.

BlendSave is configured to simultaneously and accurately weigh raw materials, combining them as a batch according to a predetermined recipe destined for predetermined processing machines. Each batch is then distributed via a rotating-arm-dispenser to its own buffer comprised of up to 50 batch buffer bins, with each buffer linked to one, dedicated processing machine. Once a signal is received from a vacuum receiver mixer/blender located at the inlet of the processing machine, material from the linked buffer is transferred via a delivery pipe to the mixer. The volume within a buffer bin and that of the linked mixer is adjusted so that the second can accommodate the first, producing exceptional batch uniformity. Blending in-line prevents the risk of material segregation during conveying.

The BlendSave innovative in-line blender is filter-less, eliminating the need for cleaning.

With dedicated weighing chambers that eradicate the risk of cross-contamination, BlendSave offers a unique solution that eliminates many manufacturing challenges when working with a variety of resins, recycled plastics (regrind and PCR resins) and other types of raw materials such as compounds and additives.

Each of the 14 up to 40 weighing chambers can be configured as a 5.28 gal (20-liter) weighing chamber or as a three-liter weighing chamber, with potential throughput of up to six tons per hour. Weighing in parallel allows for the use of smaller load cells, affording superior batch accuracy at greater throughputs.

Depending on the number of masterbatches (additives and/or colors), they can either be dispensed via the BlendSave or by integrating a single component gravimetric feeder. The LIAD Smart ColorSave 1000 precision dosing unit provides significant savings in the cost of the additives.

BlendSave eliminates the need for individual batch blenders for each processing machine. Enhancing operational uptime due to reduction of maintenance downtime due to formulation change-overs.

BlendSave – Ability to Expand and Scale

Innovative filterless vacuum receiver mixer mounted in-line ensures proper mixing.

A single BlendSave system is modular in design allowing configurations that can service 2, 4, 6, 10, 20 or up to 50 processing machines. As a plant grows, BlendSave can grow with it.

BlendSave provides full monitoring and control of customized job status, batch auditing, historical graphs and performance reports for each machine and job via an interactive PC dashboard or by linking BlendSave to a factory’s ERP platform, resulting in total communication and real-time monitoring integration with the operation’s production plant.

Conclusion

Conclusion

The convergence of Industry 4.0 is leading the charge towards the development of smarter and more efficient factories. BlendSave allows manufacturers to improve their efficiency by simplifying and streamlining the workflow process, resulting in faster production of materials with greater quality control. The result is new opportunities for business growth through automation.