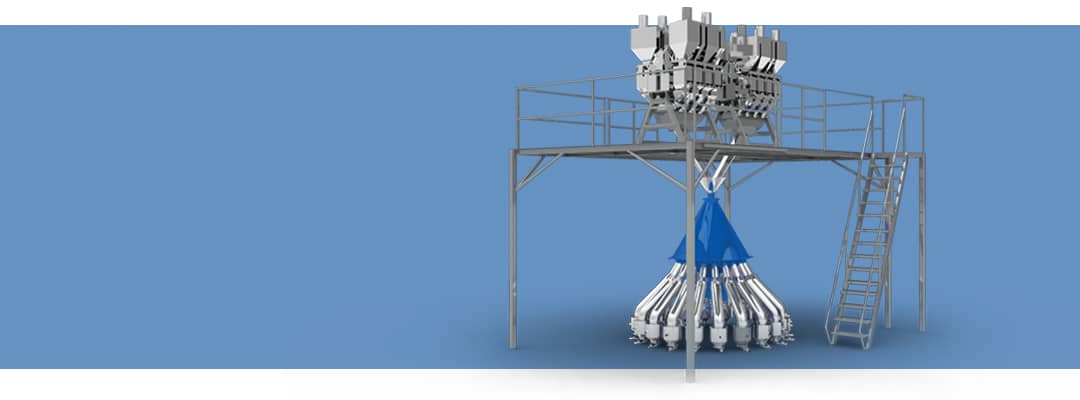

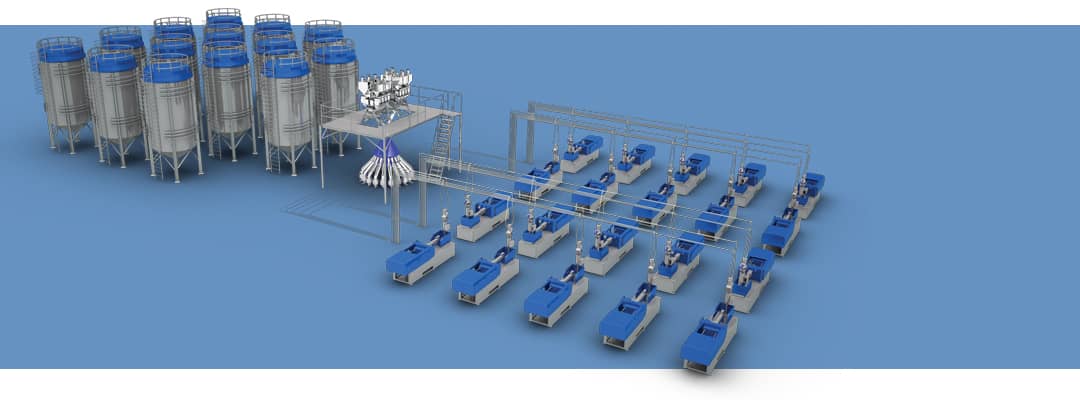

Central Blending and Automated Material Distribution System

The industry’s only central blender that:

- Blends up to 40 materials, up to 50 machines, and at rates up to 6,600 lbs/hr (3,000 kg/hr)

- Delivers any recipe, to any machine, at any time

- Mixes on the machine to ensure a homogeneous blend as the materials enter the feed throat

- Automates the material distribution to the machines…no more manifolds, hoses to switch, or mistakes

- Ties into a plant’s ERP system to support lights-out automation

- Reduces labor costs associated with material or color changes

- Integrates with any central vacuum conveying system

- Flexibility: Blends up to 40 materials, for up to 50 machines, each with a different recipe.

- Precision: Each ingredient is weighed separately for a precise batch.

- Cost savings: No bins to clean-out, no hoses to switch, no mistakes

BlendSave’s unique, dedicated recipe transfer design (OctoBatch™) eliminates sending the wrong recipe to the wrong machine.

No more complex hose configurations; no operator error.

For a more detailed discussion about how BlendSave reinvents plastic resin blending, view the white paper, watch the video, download product literature, call Doug Brownfield at 914-320-1521 or contact Ampacet.