Delivers any resin recipe to any machine at any time, for “lights out” operations

See BlendSave Compact in action at NPE2024:

Ampacet LIAD in South Hall Level 1 – Expo Hall — S22097

Ampacet LIAD has introduced LIAD Smart BlendSave® Compact, an automated resin management and blending system for new and existing operations with up to 10 machines and limited available space.

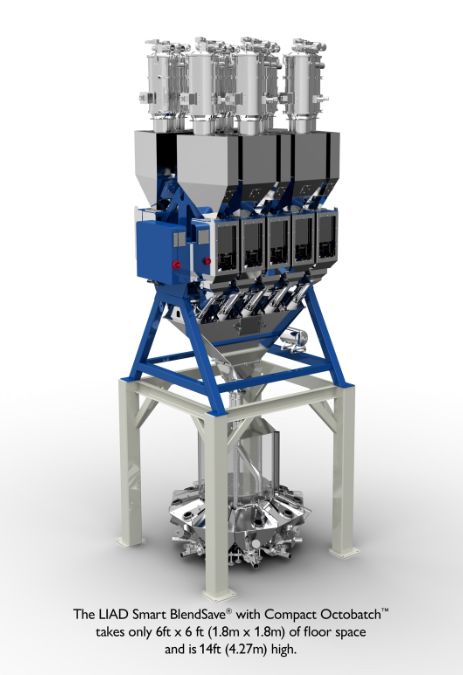

LIAD Smart BlendSave Compact uses patented weighing and blending technology to manage the increasing number of resin and PCR materials and recipe change requirements demanded by today’s processors. This smaller system includes a compact, dust-tight Octobatch automated manifold for up to 1500 kg/hr or up to 3,300 lbs/hr total throughput. BlendSave Compact weighs resin materials of up to 40 ingredients and distributes individual blends to any 10 machines for total flexibility, unmatched accuracy and automated blending of custom recipes. The compact model takes only 6ft x 6 ft (1.8m x 1.8m) of floor space and is 14ft (4.27m) high.

BlendSave Compact precisely weighs each ingredient individually for accurate batches and delivers them to the machines using dedicated material lines. A separate storage and weigh hopper for each raw material means there are no clean-outs required, no hoses to switch and no operator mistakes.

“BlendSave’s centralized precision weighing and mixing at the machine provide an ROI value and flexibility previously thought to be unachievable in typical batch blending today,” says Doug Brownfield, Commercial Director, LIAD Smart. “BlendSave Compact will enable existing facilities with fewer machines to take advantage of the system’s accuracy with zero operator interface and zero cross-contamination. BlendSave Compact enables automated blending while using a simple computer tablet to operate the blending process of all the facility’s machines.”

Unlike conventional blending systems, which can be inefficient and overly complex, BlendSave accurately weighs each ingredient individually and conveys a unique recipe through dedicated lines to a mixer on each molding machine or extruder, eliminating the risk of material contamination and segregation during conveying. Through ERP integration, the recipe selection function is managed automatically, virtually eliminating manual setup and daily operator interactions and enables true “lights-out” operations, a competitive advantage within the highly competitive plastics industry.

BlendSave’s automated manifold system, OctoBatch, distributes the individual ingredients of a recipe to as many as 10 hoppers, one dedicated for each machine, eliminating the risk of contamination and human errors that result in downtime. BlendSave’s total traceability and verification of raw materials in each batch formulation, real-time data management of all resin ingredients per run, per shift, for the entire operation through a centralized control and existing ERP systems assure adherence to Industry 4.0 objectives.

Ampacet LIAD also provides the option to integrate LIAD Smart ColorSave gravimetric feeders on the machines, which will significantly save on additive and color usage and enable quick color changes without the threat of contamination.

BlendSave Compact joins the larger BlendSave automated resin management and blending system introduced in 2021, which features up to 40 individual weighing chambers and serves up to 50 processing machines with a potential throughput of up to 3,000 kg/h or 6,600 lbs/hr.

For product information, visit https://www.ampacet.com/blendsave or contact Doug Brownfield, douglas.brownfield@ampacet.com

About Ampacet

Founded in 1937, Ampacet Corporation is a leading global masterbatch supplier committed to designing innovative custom color, special effect, high performance and sustainable products and solutions. Ampacet also manufactures LIAD machinery and feeders for the plastics industry aimed to improve efficiencies in plastics manufacturing. Headquartered in Tarrytown, N.Y., Ampacet employs more than 2,000 people worldwide, with 24 manufacturing sites including technical and color development centers in 17 countries throughout the Americas, Asia and Europe.

About LIAD

Ampacet LIAD pioneered the single component gravimetric feeder for injection molding machines and is the leading developer of innovative feeders, blenders and real-time quality control color solutions for the plastics industry. Look for the LIAD Smart label to ensure the highest quality accuracy.

Ampacet introduces LIAD Smart BlendSave® with Compact Octobatch™ a space-saving automated resin and blending system that provides optimal management of ingredients and processing for plastics plants.