Additives, which enhance and reduce handling problems, are used extensively in the manufacture of polyolefin films. In their natural state, most polyolefins exhibit a degree of ‘tackiness,’ and therefore cannot be readily processed into packaging films without the presence of additives to ease their ability to “separate and slide.”

“Slip” additives are used to reduce a film’s resistance to sliding over itself or parts of converting equipment. Commercially important slips can be found in the chemical family known as amides, and are typically referred to as “fast bloom” (oleamide) and “slow bloom” (erucamide) additives. Other amides are used specifically for special processes (e.g. higher heat extrusion coating applications or customized mixtures where balancing slip and antiblock properties are critical.)

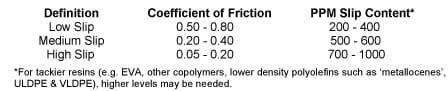

The effectiveness of slip additives are normally determined by the coefficient of friction (COF) it allows, which is measured using ASTM D-1894, “Standard Method of Test for Coefficient of Friction of Plastic Film.” COF is a ratio of the force required to slide one layer of film across another relative to the gravimetric force exerted on it. Loosely defined, films can be characterized as “low, medium, or high slip” as follows:

The most common slip agents used for polyolefins are long-chain, fatty acid amides, with amides from oleyl (single unsaturated C-18) through erucyl (C-22 single unsaturated) being utilized. Slip agents are effective because of their natural tendency to “bloom” to the surface of the film after extrusion. Different slip agents have different rates of surface bloom and COF reduction. Hence, a single slip agent might not necessarily perform in all of a customer’s desired applications.

In general, the shorter chain length amides tend to bloom to the surface more rapidly, but are less thermally stable. Higher chain length amides have a slower rate of bloom, with higher thermal stability. While it might initially seem that a faster bloom rate always offers advantages, many film processors would prefer a slower rate of exudation. This is particularly true for roll stock, where a low COF film could cause winding difficulties and “telescoping” of rolls. Slower rate of exudation of the slip agent can also result in easier film treatment (i.e. corona treating immediately after extruding the film.) Excessively high amounts of any slip agent make corona treatment very difficult.

Properties of Slip Agents

- The migration of the slip agent takes time, and the ultimate COF may not be obtained until 7-10 days after extrusion (depending on amide used.) Typically, the vast majority of COF reduction takes place within 24-48 hours.

- Slip additives must be tailored to the process and desired end-properties by the processor. In some cases, an oleamide with a quick surface bloom is needed, while in other cases a slower blooming amide is indicated.

- High levels of slip can cause problems with the surface treatment of the film as well as interfere with printability and sealability.

- The amount of slip agent must be reduced as the thickness of film is increased to maintain the same COF.

- Small amounts of slip additives not only enhance the “hand” of film, but also aid in processability.

- Slip additives can be effective in enhancing mold release properties in molding processes.

Product Line

Ampacet makes a broad variety of slip concentrates designed to fit various needs in terms of bloom rate, as well as base resin requirements. Slip concentrates are available in a variety of polyolefins, making them more compatible with polypropylene and other resins used for films.