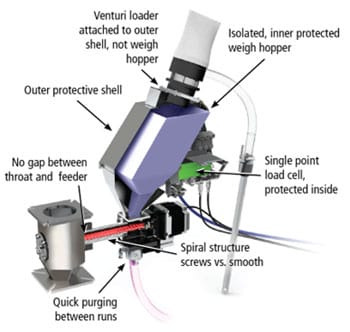

Ampacet has introduced the LIAD Smart ColorSave® 1000, the only gravimetric feeder that features an outer protective shell with an inner floating weigh hopper and single-point load cell to ensure accuracy, even in industrial settings affected by vibration and other outside influences.

ColorSave 1000 precision, the highest in the industry in additive feeding, enables savings of up to 35% on masterbatch use when compared to remote batch blending systems, up to 15% compared to a batch blender at machine throat and up to 50% compared to a volumetric feeder.

“The unmatched accuracy of ColorSave 1000 enables manufacturers to reap significant savings in masterbatch and production costs,” says Doug Brownfield, Commercial Director. “ColorSave pays for itself with potential savings of 0.5% of additive per cycle.”

Other benefits of the feeder include user-friendly design, which allows operators to quickly empty components between jobs through a quick-purge auto system, resulting in significant savings on labor and production time. In addition, the loss-in-weight controlling function allows optimum adjustment of operating points. The ColorSave 1000 features automatic calibration, which enables processors to consistently feed at the desired set point.

Part of the LIAD Smart family of feeders, ColorSave 1000 can be used with any injection molding, extrusion and blow-molding machine and is capable of integration with the LIAD Smart SpectroTM, real-time inline color management technology.

ColorSave 1000, available for the first time in North America, uses patented technology developed by recently-acquired LIAD Weighing and Control Systems, a pioneer in plastic manufacturing technologies and the leading developer of feeders, blenders and quality control equipment.

For product information, visit https://www.ampacet.com/colorsave-1000/ or contact Doug Brownfield, douglas.brownfield@ampacet.com